Battery Time

The batteries arrived and this opens an entirely new chapter in design and learning. Not only is there the mechanical design elements of assembling and installing the battery pack, there are the safety challenges. Compared to gasoline, I believe batteries are safer and easier to work with, but society's false sense of security with gasoline causes some initial concerns.The batteries of choice for Jane are the CALB CA60FI. These were introduced last year and the reviews are all very positive. These were sourced from Shift-EV in Albany Oregon. Kirk is a true expert on EV conversions.

The chemistry is LiFePO4 (Lithium Iron Phosphate) and these offer 60AH at 3.2V nominal. The pack will consist of 26 of these in series providing a nominal pack voltage of 83V. At a 80% depth of discharge assumption, these cells will provide 48AH @ 83V or just shy of 4 KWH. The Kelly Controller is limited to 90V input voltage, so this provide a little margin, but should still be sufficient voltage for the motor to achieve 3,600 RPM under load. Based on the best gear ratio calculations, in 4th gear, Jane will cruise comfortably at 55 MPH. 3rd Gear will yield 45 MPH. More than fast enough for this car and any city driving. There is an option final drive gear (3.44:1 --> 2.76:1) which will pull in another 13 MPH at the electric red-line.

Pack weight=26 x 4.45 lbs = 116 lbs.

If you want to see the detailed calculations, here is a spreadsheet (Called Vehicle Calculations) with the best-guesses for performance.

Charger

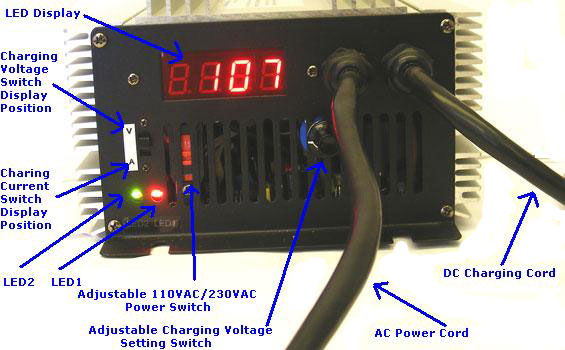

Another major component for the battery pack is the charger. We selected an automatic, adjustable voltage charger from BatterySpace which provides 16A and 1,500 Watts since there is still much debate over the best charging process to maximize longevity of the battery pack. The first charge cycle completed successfully set at 91V and the charger performed as expected, shutting off when the pack reached terminal voltage. This is plugged into a 6 hour mechanical timer and a 220V 30A outlet in the garage. It will get mounted in Jane's boot and eventually a simple cord is all that will have to be plugged in to "fill her up".This charger will fully charge an 80% depleted pack in about 5 hours. The CALB cells can take a faster charge, but there are cascading effects from increasing the charger power such as more heat, more battery wear-n-tear, larger cables and bigger power sources.

Battery Monitor

And the final critical element of the battery pack is the monitoring system. With LiFePO4 batteries, maintaining them within the proper voltage range is critical to prevent damage. There are many opinions on how best to do this but it is clear that the tighter the range of voltages, the less stress on the pack. Initially, the system will be set to keep the cells between 3.0V (discharged) and 3.5V (charging), though others say the window can be slightly larger. Battery Management Systems range in price up to thousands of dollars, depending of the size and number of cells in the pack. Since the battery is the most expensive element of the EV drive train, it makes sense to monitor and manage it diligently.For Jane's initial BMS system, passive cell monitors will be used to report and alarm if a cell goes outside of the target range. The driver will have to respond appropriately based on the situation and severity of the deviation. Not terribly different than the check-engine or over-temperature light on a gas car. A driver can choose to ignore it but damage may occur.

The CellLog 8M is a clever device. It provides monitoring for up to 8 cells and alarm capability for High Voltage, Low Voltage or if there is too much variation between the cells. It will take 4 of these to monitor the 26 cells (2x6 and 2x7). There is an minor annoyance with these devices in that they draw less power from cells 7 and 8, causing those to discharge at a slightly slower rate than the first 6 cells. Given Jane's configuration, this will only impact 2 cells which may need to be balanced periodically to bring them back in line with the rest of the pack. The four CellLogs will be mounted in a cluster on the dashboard so the driver can quickly see all 26 cell voltage values if an alarm occurs.

The last component in the monitoring system is the AH meter from Elite Power (600A 90V Combo Meter). This will act as a fuel gauge and provide a count of the Amp-Hours (AH) drawn from the batteries. Using a 600A 75mv shunt on the negative side of the battery, this meter will count the actual cumulative power (AH) fed into the controller. With LiFePO4 batteries, voltage is not a good indicator of State-of-Charge (how much energy is still available from the cell), so using AH counting will provide the most accurate fuel gauge. It will take some verification and experimenting to map AH to overall state-of-charge. More on that to follow...

Elite Power Meter

Shunt

Finally, the EVALBUM page is up for Jane. Not all of the details yet, but a great gateway to other electric vehicles. Be sure to check it out.... http://www.evalbum.com/4768